Introduction

Shop drawings are a crucial part of any construction project, serving as detailed plans that guide manufacturers, fabricators, and contractors. Unlike general design drawings, shop drawings provide precise specifications, dimensions, and materials to ensure accuracy and efficiency during construction.

In this blog, we will explore:

✔️ What shop drawings are and why they matter

✔️ The key elements of shop drawings

✔️ How they enhance project efficiency and coordination

✔️ Common challenges and solutions

✔️ The future of shop drawings in modern construction

1. What Are Shop Drawings?

Shop drawings are technical documents that detail how different building components will be fabricated, assembled, and installed. They are commonly used for:

✅ Structural elements – Beams, columns, trusses

✅ MEP systems – Mechanical, electrical, and plumbing layouts

✅ Architectural components – Windows, doors, and custom-built elements

✅ Steel and metal fabrication – Welded structures, staircases, railings

2. Importance of Shop Drawings in Construction

🔹 Why Are Shop Drawings Essential?

Shop drawings bridge the gap between design and execution, ensuring smooth coordination between architects, engineers, and contractors.

Key Benefits:

✔️ Improved Accuracy – Eliminates discrepancies before fabrication.

✔️ Time & Cost Efficiency – Prevents costly rework and material wastage.

✔️ Better Coordination – Aligns different teams (architects, engineers, contractors).

✔️ Ensures Compliance – Adheres to industry standards and safety codes.

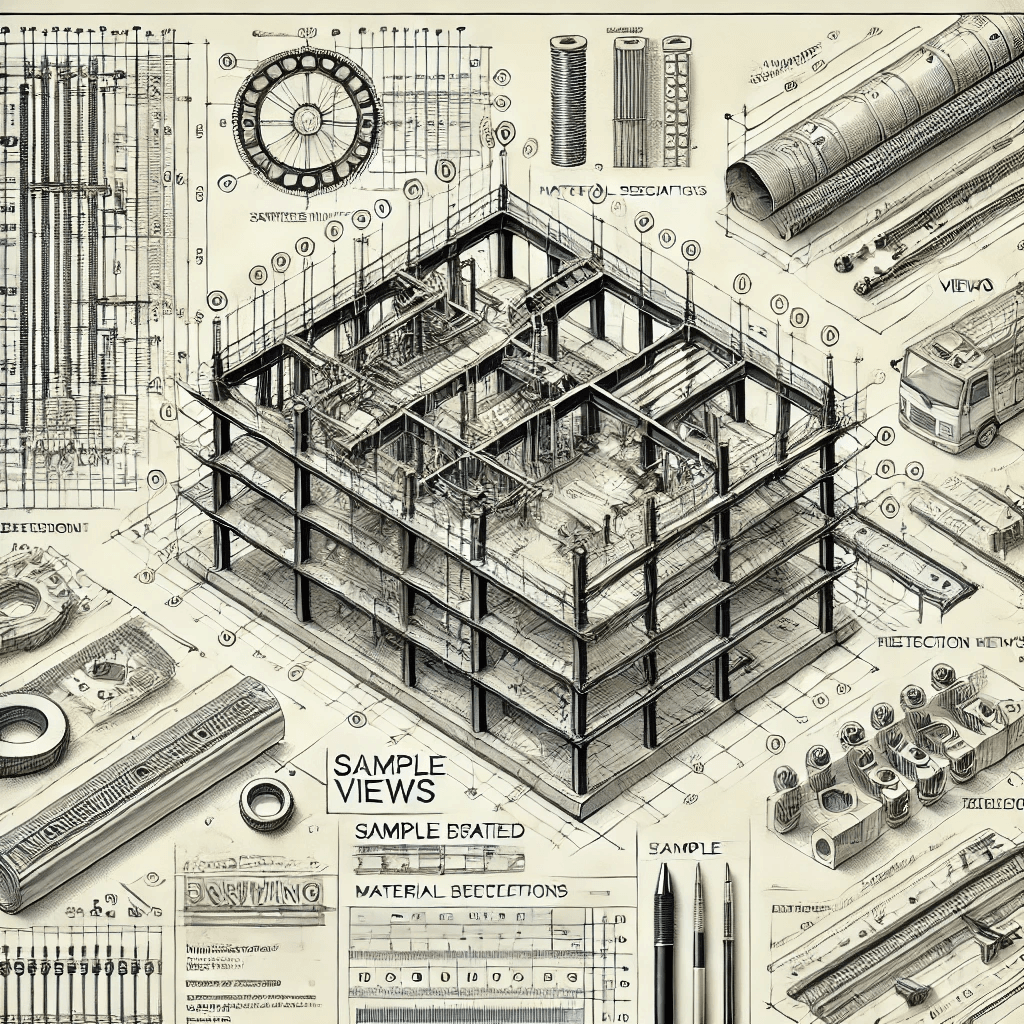

3. Key Components of Shop Drawings

A standard shop drawing includes:

📌 Detailed dimensions – Exact sizes and measurements

📌 Material specifications – Type, grade, and finish

📌 Assembly instructions – Step-by-step fabrication process

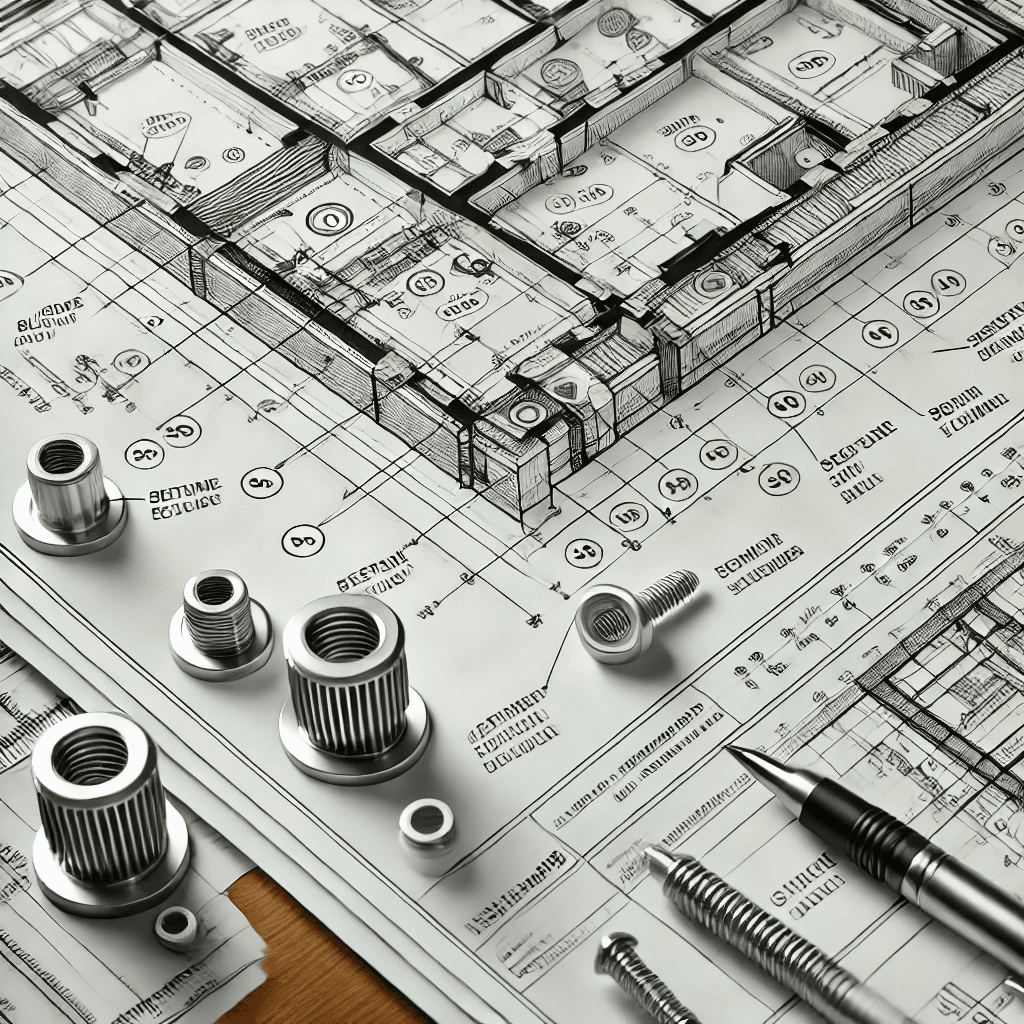

📌 Connection details – Welds, bolts, and fasteners

📌 Compliance notes – Adherence to regulations and codes

4. How Shop Drawings Improve Project Efficiency

Using shop drawings effectively can streamline construction processes, avoiding costly errors and delays.

🔹 How They Boost Efficiency:

✔️ Reduces Miscommunication – Everyone follows a single, clear reference.

✔️ Enhances Prefabrication – Off-site manufacturing speeds up construction.

✔️ Prevents Material Waste – Accurate specifications reduce excess ordering.

✔️ Speeds Up Approval Process – Quick review by architects and engineers.

5. Challenges in Using Shop Drawings & How to Overcome Them

🚧 Common Issues:

- Design Changes: Late modifications cause rework.

- Inconsistencies: Errors in interpretation lead to construction mistakes.

- Approval Delays: Slow review processes create bottlenecks.

✅ Solutions:

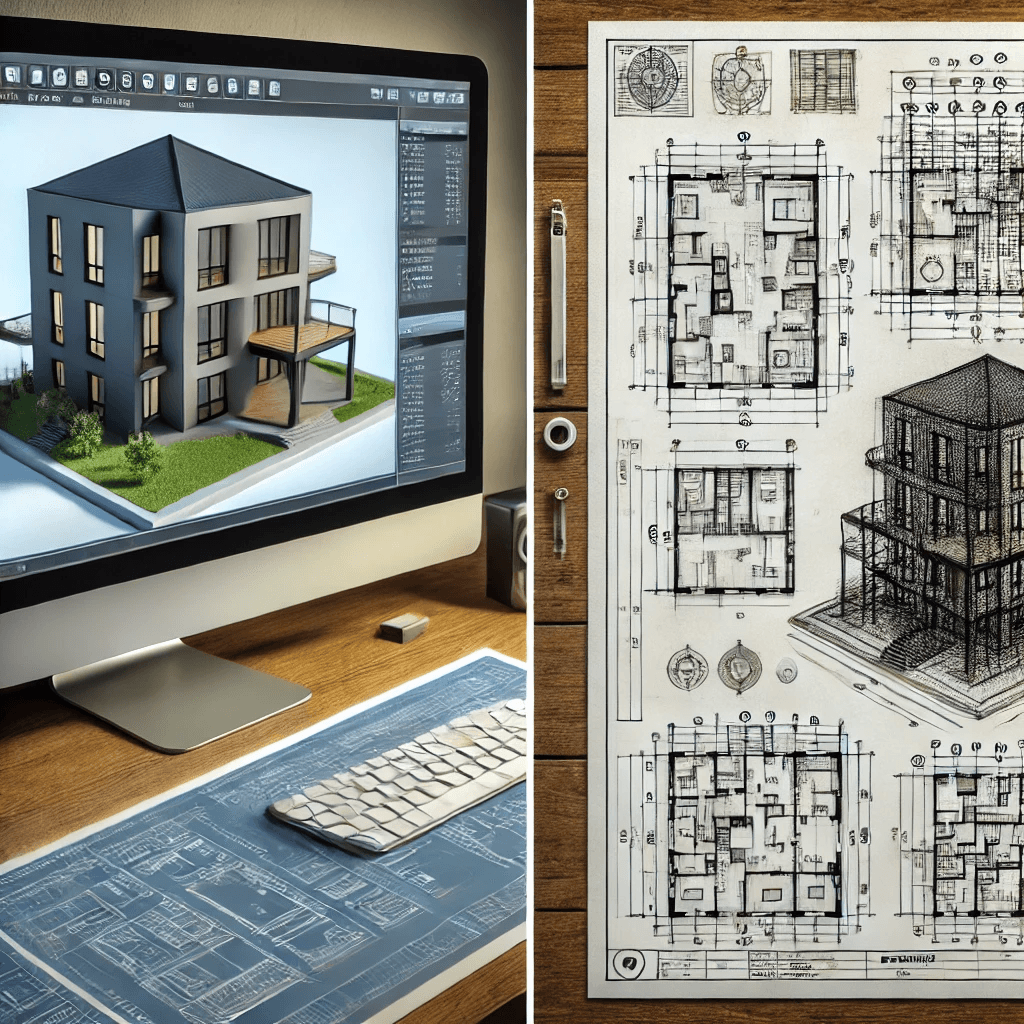

✔️ Use BIM Technology – 3D modeling reduces errors.

✔️ Implement Digital Workflows – Speeds up approval and modifications.

✔️ Collaboration Software – Cloud-based platforms improve coordination.

6. The Future of Shop Drawings in Construction

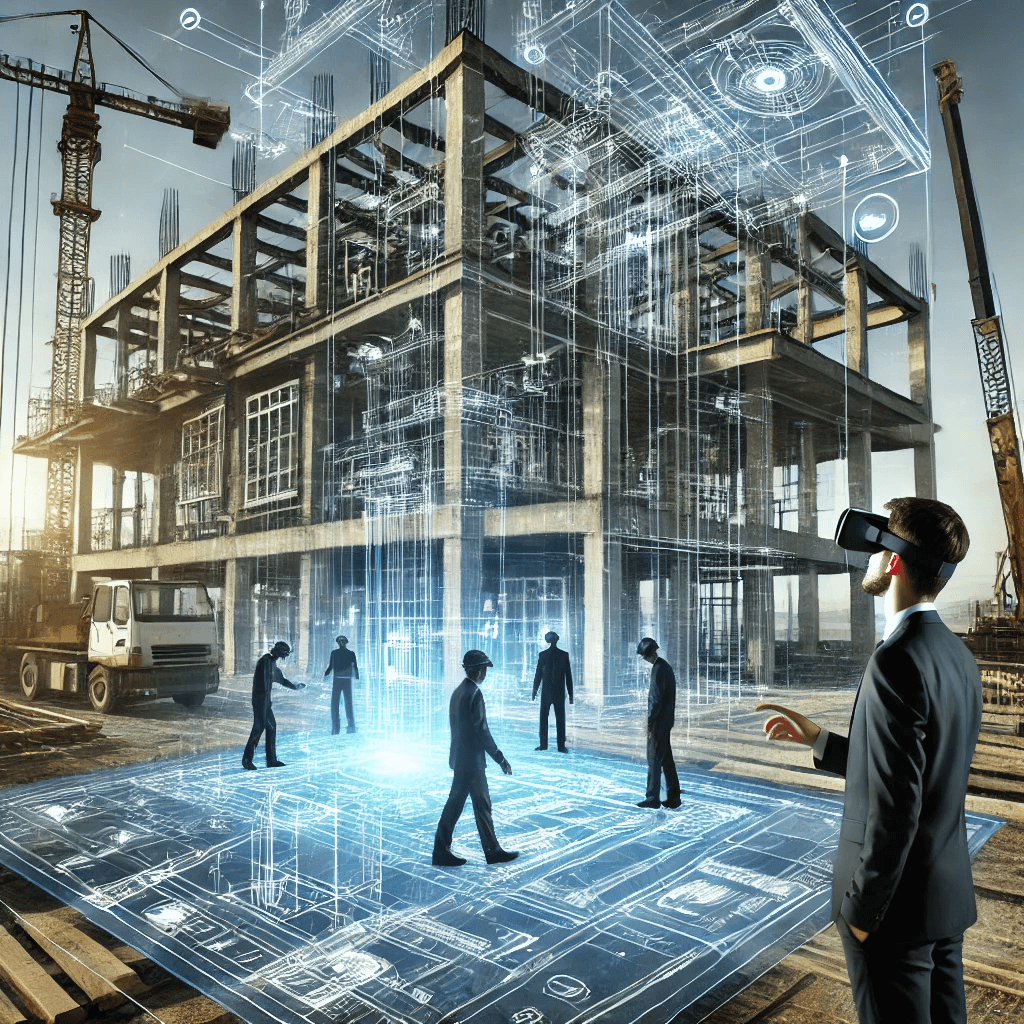

As construction evolves, digital transformation is reshaping how shop drawings are created and used.

🔮 What’s Next?

🚀 AI & Automation: Smart software detects errors before approval.

🚀 Augmented Reality (AR): Visualizing shop drawings in real-time on-site.

🚀 Cloud-Based Collaboration: Teams work on a single, updated drawing from anywhere.

🚀 3D Printing Integration: Shop drawings guide automated fabrication.

🔍 Frequently Asked Questions (FAQs) About Shop Drawings

1. What is the purpose of shop drawings in construction?

Shop drawings serve as detailed blueprints that guide contractors, manufacturers, and engineers in the fabrication and installation of building components. They provide precise measurements, material specifications, and connection details, ensuring accuracy in construction.

2. How are shop drawings different from architectural drawings?

Architectural drawings provide a conceptual and design overview of a project, whereas shop drawings focus on fabrication and assembly details. Shop drawings contain in-depth technical specifications that ensure the accurate execution of a design.

3. Who is responsible for creating shop drawings?

Shop drawings are typically created by fabricators, subcontractors, or specialized drafting professionals. However, they are reviewed and approved by architects and engineers to ensure compliance with the design intent.

4. What are the key elements included in shop drawings?

A complete shop drawing includes:

✅ Detailed dimensions

✅ Material specifications

✅ Assembly and installation instructions

✅ Connection details (welds, fasteners, bolts, etc.)

✅ Compliance with industry standards

5. Why are shop drawings important for project efficiency?

Shop drawings help eliminate design conflicts, minimize material wastage, and streamline communication between different teams involved in the construction process. This reduces errors and improves project timelines.

6. What challenges can arise with shop drawings?

Some common challenges include:

🚧 Design changes leading to rework

🚧 Inconsistencies between design and fabrication

🚧 Delays in approval and coordination

Solution: Using digital tools like BIM (Building Information Modeling) and cloud-based collaboration software can help streamline the process and minimize errors.

7. How is technology improving shop drawings?

Modern tools like 3D modeling, AI-driven drafting, and augmented reality (AR) are revolutionizing the way shop drawings are created and reviewed. These advancements enhance accuracy, improve project visualization, and reduce construction delays.

Conclusion

Shop drawings are the blueprint for construction success, ensuring precision, efficiency, and cost savings. By adopting advanced digital tools and collaboration techniques, construction teams can enhance accuracy and speed up project execution.

Want high-quality shop drawings for your next project? Contact us at TotalEnc for expert drafting and detailing services! 🚀