Understanding the Importance of Rebar Detailing

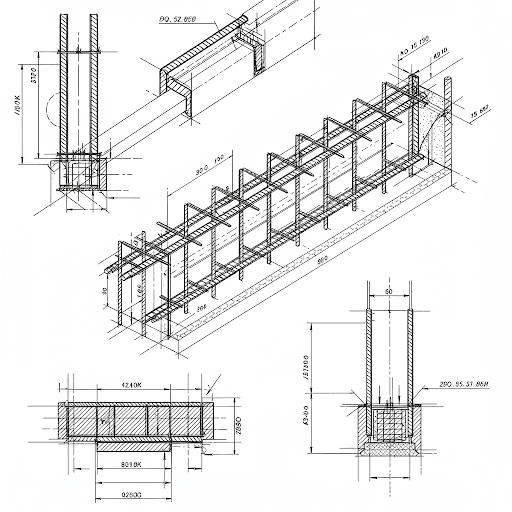

Reinforcement detailing is a crucial aspect of structural engineering, ensuring that reinforced concrete structures remain durable and resilient. Properly planned reinforcement placement enhances load-bearing capacity, preventing structural failures and improving construction efficiency.

Rebar detailing involves precise documentation of steel reinforcement specifications, including bar sizes, bending shapes, and placement instructions. With accurate reinforcement layouts, construction teams can achieve higher structural integrity while reducing material waste and labor costs.

Key Elements of Rebar Detailing

1. Accurate Reinforcement Drawings

Detailed reinforcement drawings provide essential guidance for fabricators and contractors. These drawings include:

- Bar bending schedules (BBS)

- Concrete cover specifications

- Lap and anchorage details

🔗 ACI Standards for Reinforcement Detailing – Guidelines for ensuring compliance with industry standards.

2. Compliance with Structural Codes

Adhering to international and local codes is essential for ensuring safety and efficiency. Industry standards such as ACI, ASTM, and BS codes dictate the best practices for reinforcement layout and steel placement.

🔗 American Society for Testing and Materials (ASTM) – Reinforcement material standards and guidelines.

3. Optimized Reinforcement Placement

A well-structured detailing plan ensures that rebars are positioned correctly to withstand tension and compression forces. Effective placement minimizes material usage while maximizing structural durability.

🔗 National Ready Mixed Concrete Association (NRMCA) – Concrete reinforcement and material optimization techniques.

4. Use of Advanced Detailing Software

Modern rebar detailing leverages digital tools such as:

- AutoCAD for 2D drafting

- Revit for Building Information Modeling (BIM)

- Tekla Structures for precise 3D reinforcement detailing

🔗 Autodesk Revit for Structural Detailing – Learn about BIM integration in reinforcement planning.

Benefits of Professional Rebar Detailing

1. Increased Structural Stability

Well-designed reinforcement layouts enhance the longevity and load-bearing capacity of buildings and infrastructure projects.

🔗 Structural Engineering Institute (SEI) – Best practices for reinforcing concrete structures.

2. Cost Efficiency in Construction

Optimized reinforcement placement reduces steel wastage, minimizing project costs and material expenses.

3. Faster Project Execution

Detailed reinforcement plans streamline fabrication and on-site installation, reducing construction timelines.

🔗 Construction Management Association of America (CMAA) – Efficient construction planning and management resources.

4. Enhanced Accuracy and Reduced Errors

Digital detailing reduces misinterpretation of reinforcement layouts, leading to fewer on-site modifications.

Why Choose TotalEnc for Rebar Detailing Services?

✔ Experienced Team – Skilled engineers specializing in reinforcement planning.

✔ Advanced Technology – Utilizing BIM and CAD tools for precise detailing.

✔ Compliance with Codes – Adherence to ACI, ASTM, and international standards.

✔ Cost-Effective Solutions – Optimized rebar designs that minimize material waste.

✔ Timely Project Delivery – Efficient detailing services that keep your projects on schedule.

Frequently Asked Questions (FAQs)

What is rebar detailing, and why is it important?

It is the process of creating precise reinforcement layouts to ensure structural stability and prevent failures in concrete structures.

Which software is used for rebar detailing?

Industry-standard software includes AutoCAD, Revit, and Tekla Structures for creating accurate reinforcement drawings.

How does rebar detailing reduce construction costs?

Optimized reinforcement placement minimizes steel wastage and improves fabrication efficiency, leading to cost savings.

What standards should rebar detailing comply with?

Rebar detailing should follow ACI, ASTM, and BS standards to ensure safety and quality compliance.

How can I get a rebar detailing consultation?

You can reach out to TotalEnc for professional reinforcement detailing solutions tailored to your project needs.

Contact TotalEnc – Your Trusted Partner for Rebar Detailing

For high-precision reinforcement detailing, trust TotalEnc to deliver expert solutions that enhance structural integrity and cost efficiency.

📍 Address: 8800 Ranier Ln N, Maple Grove, MN 55311

📞 Phone: +1-612-802-0406

📧 Email: info@totalenc.com

🌐 Website: TotalEnc