Understanding Fabrication Drawings

Introduction

Fabrication drawings are essential blueprints that provide detailed instructions for manufacturing components and assemblies. These technical illustrations ensure accuracy, efficiency, and consistency in the fabrication process.

Understanding Fabrication Drawings

Definition and Purpose

Fabrication drawings are technical representations that guide fabricators in manufacturing by detailing dimensions, materials, and assembly instructions. Their primary purpose is to ensure precise production and seamless assembly.

Key Components

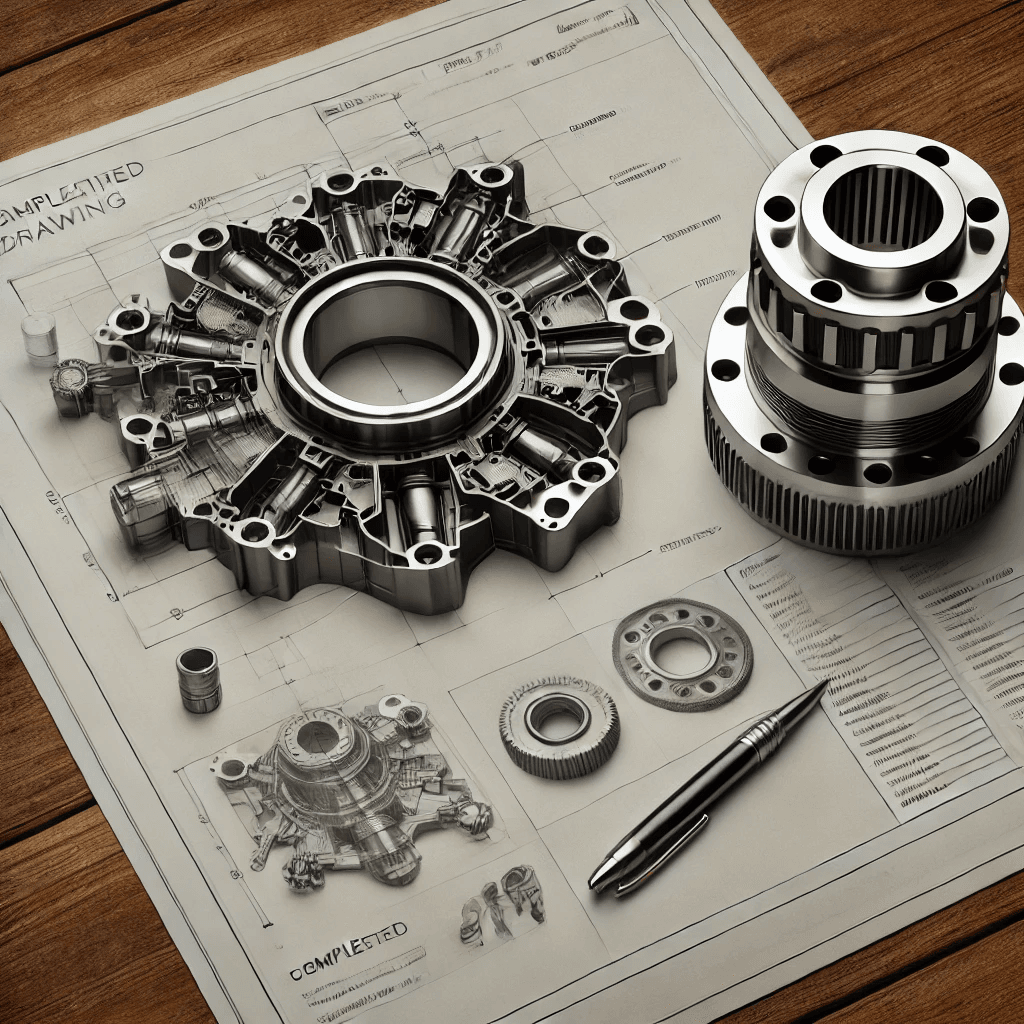

A well-structured fabrication drawing includes:

- Dimensions – Exact measurements defining size and shape.

- Material Specifications – Details about the type and grade of materials.

- Welding Symbols – Instructions for joining parts.

- Notes and Annotations – Additional instructions for clarity.

An annotated fabrication drawing with dimensions, material specs, and welding symbols highlighted

Types of Fabrication Drawings

There are multiple types of fabrication drawings, each serving a specific function:

- Detail Drawings – Provide precise specifications for individual parts.

- Assembly Drawings – Show how components fit together.

- Shop Drawings – Designed for workshop use, providing step-by-step fabrication instructions.

- Installation Drawings – Offer guidance for proper installation of the final product.

Side-by-side examples of different types of fabrication drawings

Industries That Rely on Fabrication Drawings

Fabrication drawings play a crucial role in various industries:

- Construction – Used for steel structures and building components.

- Manufacturing – Essential for machinery and equipment production.

- Automotive – Key for vehicle component fabrication.

- Aerospace – Critical in aircraft manufacturing.

Industry-specific fabrication drawings

Creating Effective Fabrication Drawings

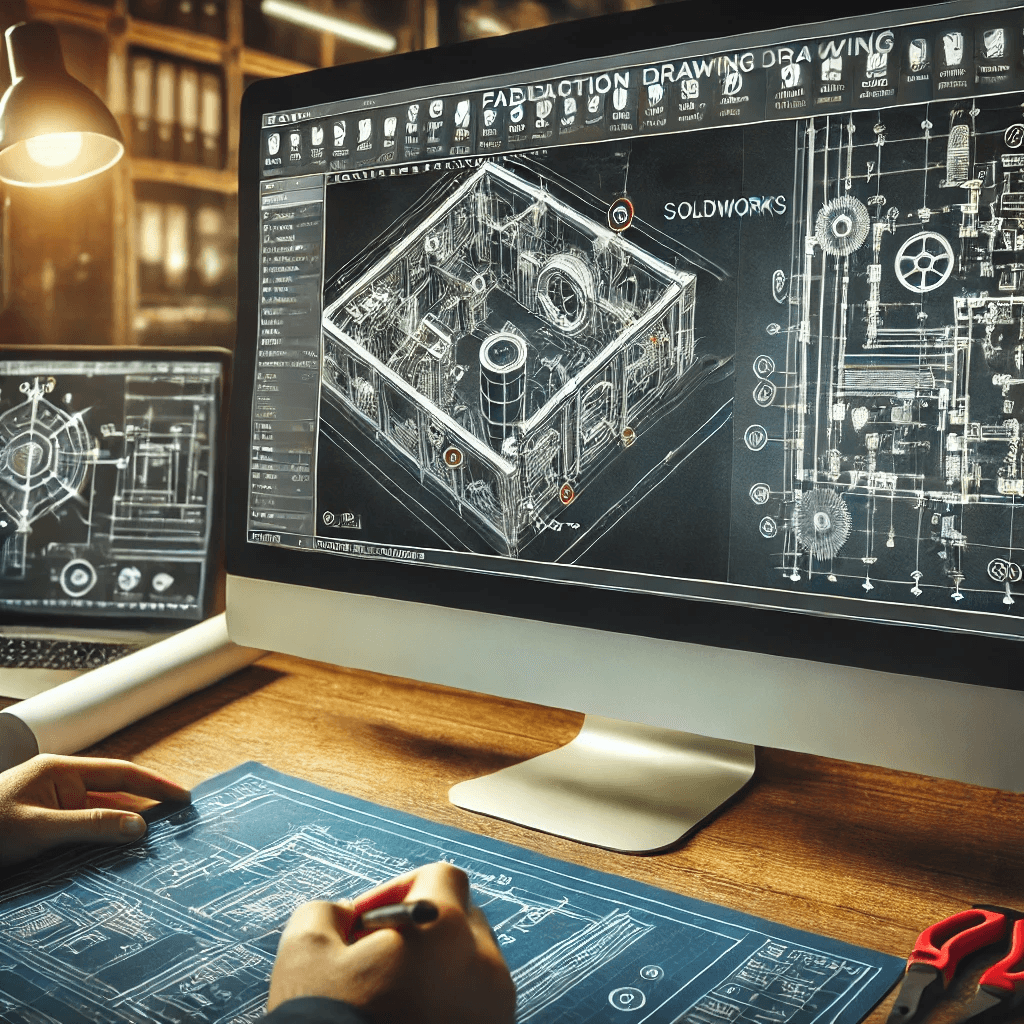

Essential Tools and Software

Popular software for creating fabrication drawings includes:

- AutoCAD – Widely used for 2D and 3D technical drawings.

- SolidWorks – Ideal for detailed 3D modeling.

- Revit – Frequently used in construction for BIM (Building Information Modeling).

A digital screen showing fabrication drawing software in use

Step-by-Step Drawing Process

- Conceptualization – Understanding the design requirements.

- Drafting – Using CAD software to create the drawing.

- Review – Checking for accuracy and compliance.

- Finalization – Making necessary revisions and preparing for use.

Best Practices for Clarity and Accuracy

- Use clear and legible fonts and symbols.

- Maintain consistent line weights and styles.

- Organize information logically to avoid confusion.

A fabrication drawing with labeled best practices

Reading and Interpreting Fabrication Drawings

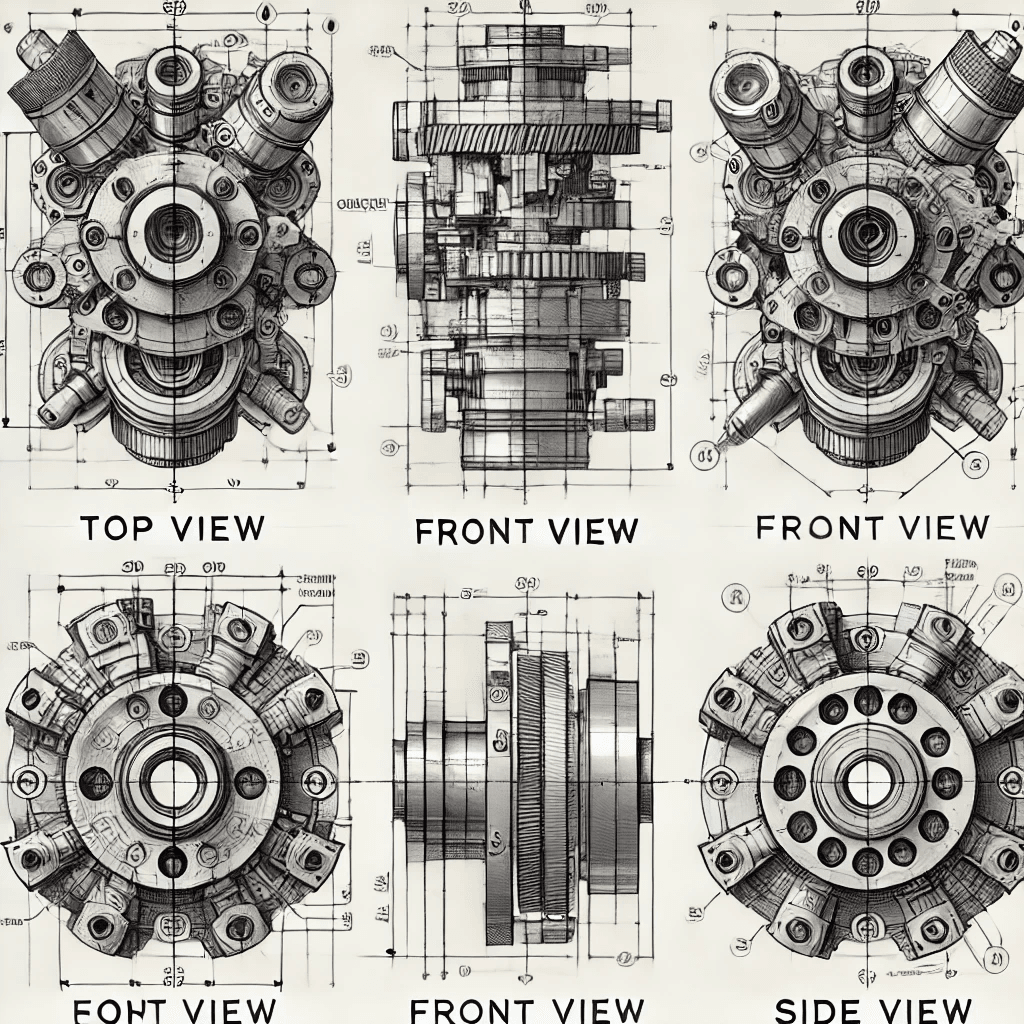

Identifying Drawing Views

Fabrication drawings typically include multiple views, such as:

- Top View – A view from above.

- Front View – A view from the front.

- Side View – A lateral perspective.

Understanding Scale and Proportions

Scale indicates the ratio of the drawing’s dimensions to the actual object’s size. Proper understanding helps fabricators visualize the final product accurately.

A side-by-side comparison of different drawing views (alt text: Fabrication Drawing Views)

Decoding Material Specifications

Material specifications include details such as:

- Type of Material – Steel, aluminum, plastic, etc.

- Grade – The material’s quality or strength.

- Finish – Any required surface treatments or coatings.

Recognizing Assembly Instructions

Assembly instructions typically include:

- Step-by-step guidelines – Instructions for putting parts together.

- Sequence of assembly – The correct order for assembling components.

An annotated material specification table from a fabrication drawing

Importance of Fabrication Drawings in Manufacturing

Streamlining Production Processes

Fabrication drawings provide clear instructions, minimizing production delays and misinterpretations.

Ensuring Quality Control

Detailed drawings help maintain consistent quality by standardizing dimensions and specifications.

Facilitating Communication Between Teams

They serve as a reference for design, engineering, and production teams, ensuring seamless collaboration.

Reducing Errors and Waste

Precision in drawings reduces manufacturing errors, material waste, and overall costs.

A factory setting with engineers reviewing fabrication drawings

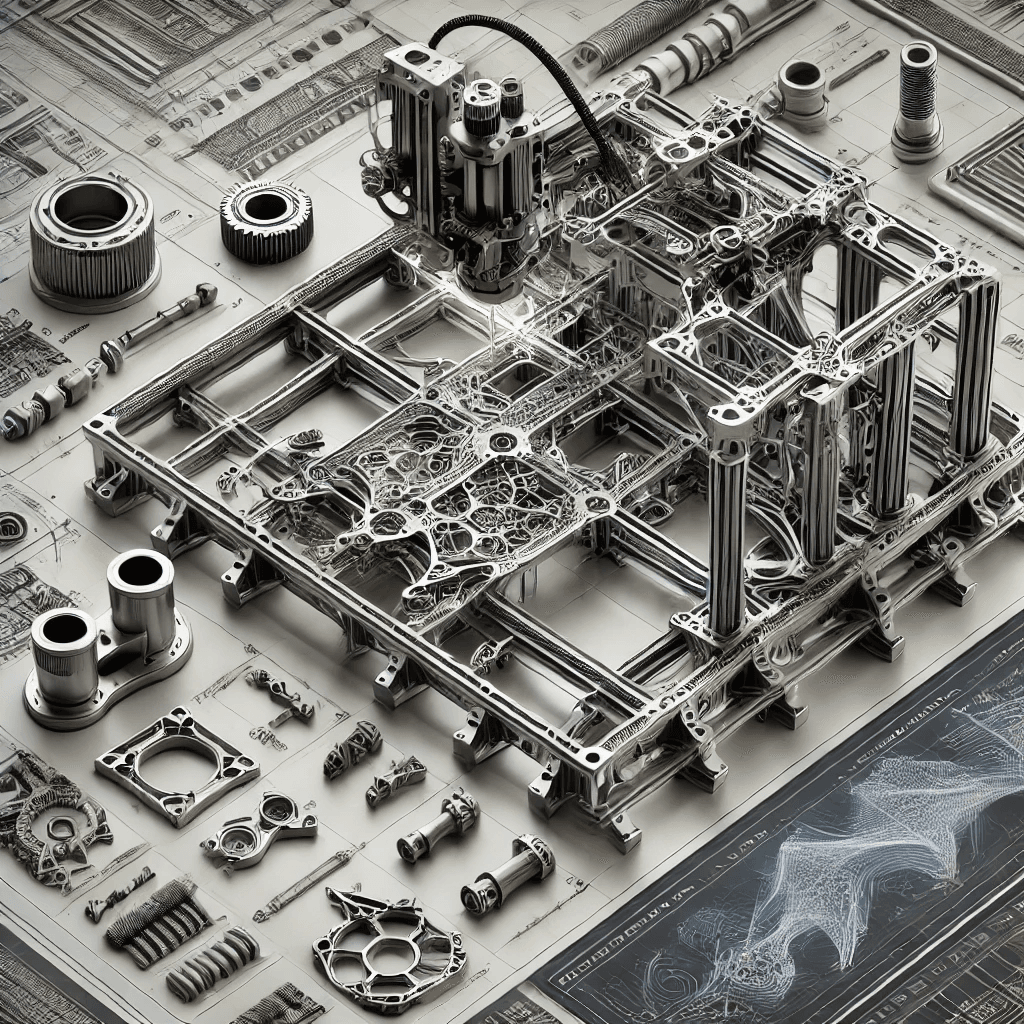

Advanced Techniques in Fabrication Drawing

3D Modeling and Visualization

3D models help teams visualize and analyze component fit before fabrication.

Parametric Design

Allows for easy modifications and scalability of designs.

Integration with CAM Systems

Combining drawings with Computer-Aided Manufacturing (CAM) automates processes, enhancing efficiency.

Collaborative Drawing Platforms

Cloud-based tools enable real-time collaboration among multiple team members.

A 3D CAD model of a fabrication project

Challenges and Solutions in Fabrication Drawing

Dealing with Complex Geometries

Using advanced software tools simplifies complex designs.

Managing Revisions and Version Control

A structured version control system ensures consistency and avoids errors.

Ensuring Compliance with Industry Standards

Regular training helps teams stay updated on fabrication standards.

Overcoming Communication Barriers

Standardized symbols and clear annotations improve cross-team communication.

Adapting to New Technologies

Continuous learning ensures professionals stay updated with evolving industry tools and trends.

A team of engineers collaborating on fabrication drawings using digital tools

Frequently Asked Questions (FAQ)

1. Why are fabrication drawings important?

They ensure accuracy, reduce errors, and streamline the manufacturing process.

2. What software is best for creating fabrication drawings?

AutoCAD, SolidWorks, and Revit are commonly used.

3. How do I read welding symbols in fabrication drawings?

Welding symbols follow standardized formats indicating type, size, and location of welds.

4. What is the difference between fabrication and shop drawings?

Fabrication drawings show overall details, while shop drawings focus on how components are made.

5. How can I improve clarity in my fabrication drawings?

Use standardized fonts, consistent line weights, and clear annotations.

Conclusion

Fabrication drawings are fundamental to precision manufacturing, providing critical details for production accuracy, efficiency, and quality control. By leveraging modern tools and best practices, industries can enhance productivity, reduce errors, and ensure successful project outcomes.