1. What Are PEB Structures?

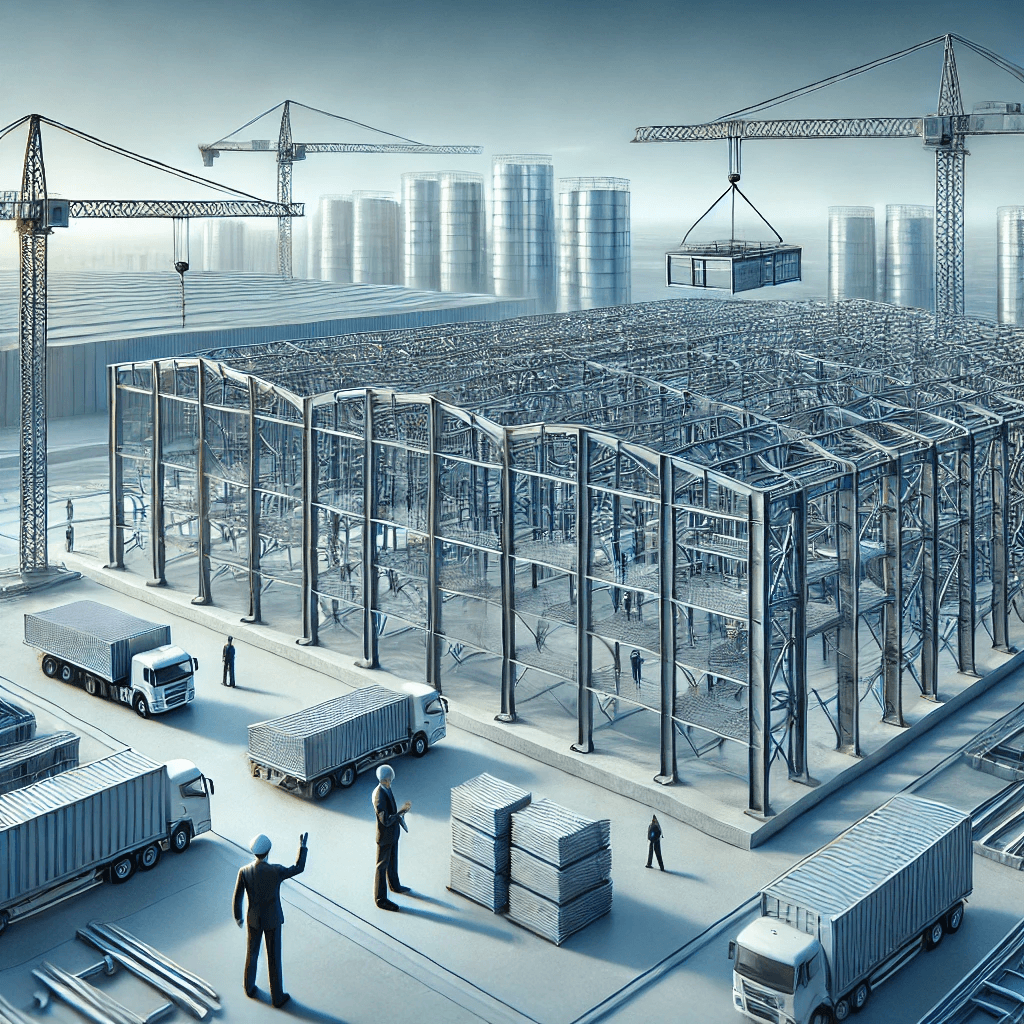

Pre-Engineered Buildings (PEB) are factory-made steel structures designed for quick assembly at construction sites. These buildings are lightweight, durable, and customizable, making them ideal for industrial and commercial applications. PEB structures have gained popularity due to their cost-effectiveness and reduced construction time. Their modular nature allows for scalable solutions, adapting easily to varying project sizes and needs.

2. Advantages of PEB Structures in Industrial Construction

PEB structures offer numerous benefits, including reduced material wastage, faster project completion, and lower labor costs. Their flexibility allows easy expansion, making them suitable for warehouses, factories, and logistics hubs. Additionally, PEB structures are environmentally friendly, as they minimize construction waste and energy consumption. Businesses can also benefit from increased safety due to controlled manufacturing environments.

3. How PEB Structures Improve Construction Speed

One of the biggest advantages of PEB structures is their rapid construction time. Since most components are pre-manufactured and assembled on-site, projects can be completed much faster than traditional construction methods. This efficiency reduces downtime and helps businesses start operations sooner. The streamlined production process ensures minimal disruption, making PEB structures ideal for time-sensitive projects.

4. Cost-Effectiveness of PEB Structures

PEB structures are a cost-effective solution for industrial projects. Their prefabrication process significantly reduces material costs, while the speed of construction lowers labor expenses. Additionally, these buildings require minimal maintenance, saving businesses money in the long run. The reduced construction waste and energy-efficient designs further enhance financial savings, making them a preferred choice for industries seeking sustainable growth.

5. Sustainability and Energy Efficiency in PEB Structures

Sustainability is a key advantage of PEB structures. Their lightweight design reduces foundation requirements, leading to less material consumption. These structures also support energy-efficient insulation, reducing heating and cooling costs. Many industries are adopting PEB structures to meet green building standards and environmental regulations. The use of recyclable materials in PEB structures further enhances their eco-friendly appeal, helping companies meet corporate sustainability goals.

6. The Future of Industrial Construction with PEB Structures

The demand for PEB structures is growing rapidly as industries seek efficient, cost-effective, and sustainable construction solutions. With advancements in technology and design, PEB structures will continue to shape the future of industrial construction, offering versatile and innovative solutions for various sectors. Smart construction techniques, including AI-driven design and automation, are expected to further optimize PEB efficiency.

Why Choose TotalEnc for PEB Structures?

At TotalEnc, we specialize in high-quality PEB structures that cater to diverse industrial needs. Here’s why we are the preferred choice:

- Expert Engineering Solutions – Our team delivers precise, customized PEB designs tailored to your requirements.

- Cost-Effective Construction – We optimize materials and labor to offer affordable solutions without compromising quality.

- Fast Project Delivery – With advanced manufacturing and streamlined assembly processes, we ensure rapid construction timelines.

- Sustainable and Durable Designs – Our PEB structures meet modern sustainability standards and are built to last.

- Comprehensive Support – From design to execution, we provide end-to-end assistance for seamless project completion.

- Advanced Technology Integration – We incorporate the latest innovations, ensuring optimized performance and efficiency.

Frequently Asked Questions (FAQ)

1. What industries benefit the most from PEB structures?

PEB structures are widely used in manufacturing, warehousing, logistics, aviation, and commercial spaces due to their durability and efficiency.

2. How long does it take to construct a PEB structure?

PEB structures can be assembled in a fraction of the time required for traditional buildings, often within weeks instead of months.

3. Are PEB structures customizable?

Yes! PEB structures can be tailored to specific design and operational requirements, including size, layout, and additional features.

4. How do PEB structures contribute to sustainability?

They reduce material waste, energy consumption, and carbon footprints, making them an eco-friendly choice for industrial construction.

5. What maintenance is required for PEB structures?

PEB structures require minimal maintenance, with periodic inspections and minor upkeep ensuring long-term durability.

6. How does TotalEnc ensure quality in PEB structures?

We use premium materials, advanced engineering, and rigorous quality checks to deliver robust and reliable PEB solutions.

7. What are the cost-saving benefits of PEB structures?

PEB structures reduce initial construction costs, minimize labor expenses, and require lower maintenance over time, making them a cost-effective choice for businesses.

8. Where can I learn more about PEB structures?

You can explore more about PEB structures and their industry applications through resources like BuildingSmart and leading construction publications.

Contact Us

Looking for top-notch PEB structures? TotalEnc is your trusted partner!

📞 Call us: +1-612-802-0406

📧 Email: info@totalenc.com

🌍 Visit us: https://totalenc.com/